FOUNDRY

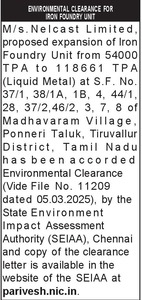

Nelcast’s Ponneri plant started commercial production in 1996. The plant produces approximately 80% Grey Iron Castings and 20% Ductile Iron Castings for the Tractor, Commercial Vehicle, Off-Highway & Railway Industries. The current casting production capacity of the plant is 42,000 Metric Tons/Year.

DEVELOPMENT

The Company has invested in facilities to achieve its goal of speedy product development of even the most complex castings.

- Utilizing the best tools in the industry like MAGMASOFT, the development team evaluates the filling and solidification process of the Iron to ensure that castings are produced defect-free from the very first time.

- Tool Design is done in-house by our Engineering team utilizing Creo Parametric CAD software. MasterCAM is used to generate CNC code from the 3D data. Tools are manufactured utilizing our 9 CNC Vertical Machining Centres of different sizes. This ensures quick and reliable development of new castings.

- Our Pattern Shop also ensures that all tooling is well maintained and serviced to ensure the quality of the castings throughout the life of the tool.

MOULDING SHOP

Any high-quality casting begins with a high-quality mould. This concept is clearly embodied in our investments in technology for producing moulds which result in castings with exceptional dimensional accuracy & superior surface finish.

The sand used in the moulds is a key ingredient in producing a high-quality mould. State of the art equipment such as PS-4 Polygonal Sieve, ASK-150 Sand Cooler and WM3-120 Intensive Sand Mixer from Kuenkel Wagner are used for ensuring a high level of quality in the output sand. The Ponneri plant utilises fully automated sand preparation plants to ensure highest adherence to strict process parameters. The Intensive Mixers is further equipped with the MiComp from Michenfelder which checks every batch for key parameters before discharging the sand to the moulding lines.

The Ponneri Plant is equipped with a Kuenkel Wagner DFM moulding line which utilizes Airpress plus 2000 and multi-piston squeeze to produce moulds of perfect quality for even castings with extremely complex contours. The line is well complemented by an automated pouring system from ABP.

- Kuenkel Wagner DFM – 1200 X 900 X 400/400 @ 60 moulds/hour

The High Pressure Moulding Line is also well complemented by our DISA Arpa series simultaneous Jolt+Squeeze Moulding Machine which has an automated mould transportation line:

- DISA ARPA – 1300 (1 Pair.) – 1200 X 950 X 400/400 mm

Due to the wide range of moulding machines that Nelcast employs, we are able to service a very diverse product range and can offer customers the most economical solution for their specific product.

MELTING SHOP

Nelcast uses Medium Frequency Induction melting furnaces for optimal metal availability and power efficiency. The Company has installed multiple Inductotherm DUAL TRAK-R plus furnaces which utilizes the latest technology in its power & control system to apply melting power to one furnace and holding power to another furnace, simultaneously to ensure close to 100% utilization during the melting process.

- 3 X 3MT Inductotherm 3500/3000 KW Dual-Trak plus

CORE SHOP

Utilizing our expertise & facilities for making cores of different types, we are able to offer customers the perfect balance of intricacy and economy via utilization of the right type of core for each specific product through our extensive facilities. The plant is also equipped with an automated sand drier and cooler to avoid casting defects due to moisture in the core:

QUALITY CONTROL

Quality is the hallmark of Nelcast. Products undergo rigorous quality checks at every stage of production. In order to ensure the physical & dimensional properties of our products, our Quality Control Department has facilities for:

- 22 Elements Spectrometer from Thermofischer ARL, Switzerland for determining precise chemical composition of the metal.

- Optical Microscopy equipment with photographic attachment and Image Analyzer.

- Complete Sand testing facilities.

- Hardness Testing Machine.

- Ultrasonic machine for detection of sub- surface defects.

- Carl Zeiss 3-Dimensional Co-ordinate Measurement Machine.

- FARO Arm 3D LASER Scanner.

- Tensile Testing Machine.

OUR REACH

Plant II– Ponneri

![]()

Nelcast Ltd,

Madhavaram Village,Tiruvallur District,

PONNERI-601 204, Tamilnadu, India.

![]() +91-044-27974165, 27971506

+91-044-27974165, 27971506